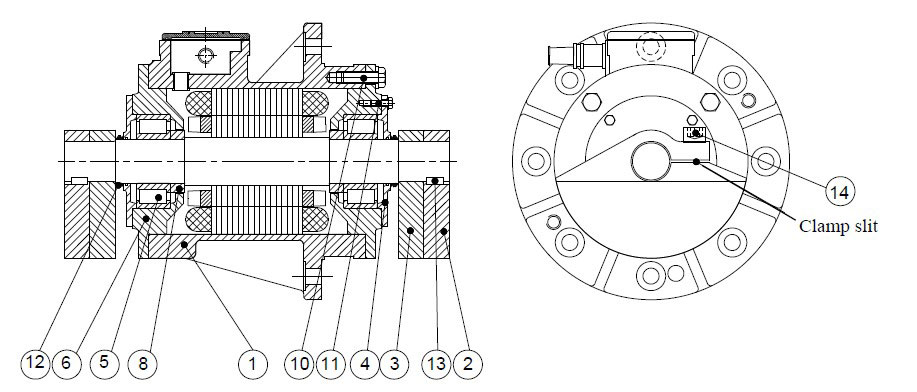

1. Heat the internal race of the new cylindrical roller bearing (5) and spacer (8) to between approx.80°C to 100°C (oil bath or hotplate) and push them onto the shaft up to the stop.

2. Allow the internal race and spacer to cool down so that they sit firmly on the shaft.

3. Clean the bore of the bearing plate (6) and apply a thin layer of LOCTITE 270.

4. Press the outer race of the cylindrical roller bearing (5) into the bore of the bearing plate (6). Make sure that the outer race does not wedge.

5. Fill the specified grease into the roller of the cylindrical roller bearing. Use the specified grease and fill two thirds of the space in the bearing plate (6) and bearing cover (4).

6. Use the attachment bolts (11) to attach the bearing cover (4) to the bearing plate.

5. Pull out the shaft approx.30 mm and then push on the bearing plate (6), with the installed cylindrical roller bearing (5), onto the internal race of the bearing, so that it is centered.

7. Subsequently, push the bearing plate, together with the shaft, to the chamfer on the housing.

8. Install all of the attachment bolts (10) and uniformly tighten.

9. During installation, in order to prevent the rollers of the cylindrical roller bearing.

10. Wedging on the inner race, continually rotate the stub shaft in both directions by hand. Otherwise, premature damage to the bearing can occur.

11. Uniformly tighten the bearing plate as far as it will go.

12. If possible, install a new V-ring (12). Apply grease also to the sealing lips of the-ring.

13. Install the inner flyweights (3), the scale must be in the correct position.

14. Install the key (13).

15. Install the outer flyweights (2) in the correct position and tighten the attachment bolts (14).

16. Set the inner flyweights according to the position marked or recorded previously, install and fully tighten the bolts.

17. Use the torque wrench and torque tighten the attachment bolts.

If several motors are repaired simultaneously, make sure that the components of the individual vibration motors are not exchanged. If you still have questions about installing the bearing of the vibration motor, please contact us.